Choosing a circular saw blade

Anti-kick Saw Blades: A particular circular saw blades (CSB) shoudler design that is engineered to improve the ease of cut and reduce the effect of the saw blade kicking back due to overfeeding.

Arbor: The saw motor shaft that rotates the saw blade. Often referred to as the mandrel.

Bevel: Angles on a carbide tooth CSB. Teeth can have a single bevel, two bevel or no bevel at all. Types of bevels can alternate from tooth to tooth on a given blade. The bevel is what gives the blade its specific cutting pattern.

Chipper: A cutting tool that is placed between the outside blades of a dado set to adjust the width of the cut.

Chipping: The condition caused when the saw blade lifts and tears the wood fibres as it exists the material. This causes the edges to be ragged.

Coating: Specifically formulated coatings that stay slick. Coating a blade reduces heat in 2 ways. It minimises friction and binding and resists pitch and gum build-up.

Combination Saw Blade: Saw blades used for both ripping (cutting with the grain of the wood) and crosscutting (cutting across the grain).

Crosscut: To cut or saw against the grain of the wood.

Cutter: Outside blades used in dado blades.

Expansion Slots: The spaces that allow a blade to expand as it heats up during cutting. It eliminates warpage by cooling the blade.

Ferrous: Of or containing iron.

Finishing Saw Blades: A saw blade with a higher tooth count to provide smoother cuts. Typically refers to 7 1/4 inch blades with more than 40 teeth and 10 inch blades with more than 60 teeth.

Framing Saw Blade: Carbide tipped saw blade used to make fast cuts in all types of wood (the fastest cutting is achieved with lower tooth count saw blades).

Kerf: This is the width of the cut, including the steel plate thickness plus any overhang on a carbide blade.

General Purpose Saw Blades: Lower tooth count saw blades. Used primarily for fast cross cutting and ripping.

Gullet: The space between teeth that clears the work piece or chips after the cut.

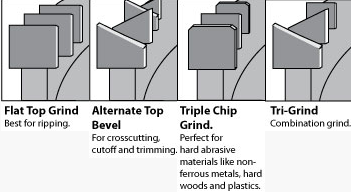

Grind: There are many types of tooth grinds, a few of the basic ones are:

Hollow Ground: A concave bevel edge on a tool.

Hook Angle: The “attack angle” of the teeth. Harder, more brittle materials need a shallower angle to ease pressure against the materials and reduce chip out. Softer materials require a sharper angle to reduce chip out.

Miter: The process of cutting material for an equal joint.

Nonferrous: Materials or metals not of or containing iron, such as aluminium, copper, brass and lead.

Plate: The steel body of the carbide blade on which the teeth are welded.

Plane: In woodworking, to make a surface smooth or even.

Rabbit: An open-ended cut made along the end of a workpiece that receives or interlocks with another piece to form a joint.

Ripping: The process of sawing a board in the direction of the grain of the board.

Run out: The amount of left to right movement a saw blade makes during operation. Often referred to as wobble or warp.

Stiffening Collar: A flat collar that mounts on the saw arbour directly next to the blade. They are used to make more accurate cuts and dampen the sound the saw generates.

Shim: A thin, often tapered piece of material such as metal or wood used to fill in space between things. In dado operations, a round disk used to make a wider cut.

Tear-out: A condition in which the saw blade tears out the grain of a work piece.

Tempered: To bring the steel plate of a saw balde to a desired hardness by reheating or cooling.

Thin kerf saw blades: A saw blade with a reduced kerf, or cut width.

Comments

Add comment