Using Pneumatic Tools For DIY

Pneumatic power tools are used around the world for their convenience and ability to speed up DIY project. Here in South Africa we still have to discover the practicality of using pneumatic power tools.

While there isn’t a large variety of pneumatic tools available, there are pneumatic nail guns priced from around R2000 that are a good investment if you plan to do a lot of DIY in the home, or out on site. When used in conjunction with wood glue, pneumatic nail guns not only cut down on the time spent assembling and finishing projects, but also offer an invisible and strong method of fastening.

A pneumatic nail gun requires a compressor to operate. The compressor hose fittings are connected to the pneumatic nail gun and locked in position. It is important to ensure that clips and fittings are tightly secured at all times. Regularly apply WD-40 to the fittings to ensure smooth operation.

Pneumatic tools are used in conjunction with a compressor and it’s important to buy a compressor that has sufficient output (pressure and air output) to power your particular pneumatic tool. AirCraft compressors from Vermont Sales are available in various sizes and can be used to power up a small artist’s airbrush or a pneumatic nail gun. The AirCraft compressor shown below offers max. 6 bar pressure – ample output if you are using for the projects shown at the bottom of this page – where continuous nailing in not required, as this allows the compressor to build-up pressure in between nailing.

When setting up a compressor for the first time, read the instructions carefully to ensure the unit is used in accordance with the manufacturer’s recommended guidelines.

The air hose should be of a diameter as recommended by the manufacturer for use with the compressor but a minimum pressure rating of 10 bar. Incorrect hose size will decrease the nailing performance. If in any doubt as to the correct compressor and accessories, get in touch with the respective pneumatic tool or compressor supplier.

Pneumatic tool oil must be used to lubricate the nail gun after every 50 or so nails. A couple of drops of pneumatic tool oil can be placed in the air fitting and the pneumatic air gun fired a couple of times after introducing oil.

A pneumatic nailer should offer easy loading of nails (brads), and this particular model has an easy-open magazine

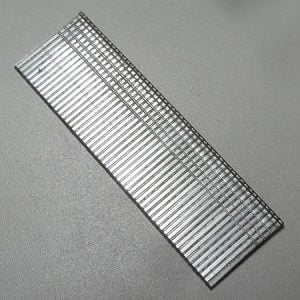

The nails (brads) come in various lengths and can be purchased in lots when buying your pneumatic nailer. It’s always a good idea to buy a selection of sizes to ensure you are ready for any project.

ABOVE AND BELOW: Use a pneumatic nail gun to attach moulding to furniture pieces.

BELOW: Use a pneumatic nail gun to build up layers of trim to add architectural detail to doors and windows.

BELOW: Use a pneumatic nail gun to assemble projects without any visible screws or fastenings.

Comments

Add comment